Feature of UL Steel Fire Door Frame

As a fire door manufacturer, steel door frame is the mainstream choice in the American standard market, and its characteristics of high strength, low cost and easy installation make it widely used in commercial, industrial and public buildings. The following is a detailed analysis of the core characteristics of the American standard steel fireproof door frame from the aspects of material, structure, fire performance, installation adaptability, certification requirements.

1. Material and manufacturing standards

(1) Type of steel

Cold rolled steel sheet (ASTM A1008) : Smooth surface, precise dimensions for high precision door frames.

Hot-rolled steel sheet (ASTM A36) : less costly, but requires additional anti-corrosion treatment (such as galvanizing or spraying).

Galvanized steel (ASTM A653) : Rust resistant, suitable for wet environments (e.g. basements, coastal areas).

(2) Thickness standard

Standard door frame: 16-18 gauge (1.2mm~1.5mm)

High fire rating door frame (2-3 hours) : 14 gauge (1.6mm~2.0mm) to enhance deformation resistance.

Key points:

American standard steel door frames usually use 16 gauge cold-rolled steel, taking into account strength and cost.

High fire rating (e.g. 3 hours) The door frame should be thickened or the interior filled with fireproof material (e.g. Mineral wool).

2. Structural characteristics

The structural design of the American standard steel door frame directly affects the fire performance, installation method, and sealing, which are mainly divided into the following types:

(1) Classified by notch type

Type Features Applicable scenarios

Single Rabbet - suitable for single doors

- Simple structure, low cost ordinary fire door (such as office, stairwell)

Double Rabbet - Used for opening doors

- Ensure fire sealing of two doors when closed large access door (warehouse, workshop)

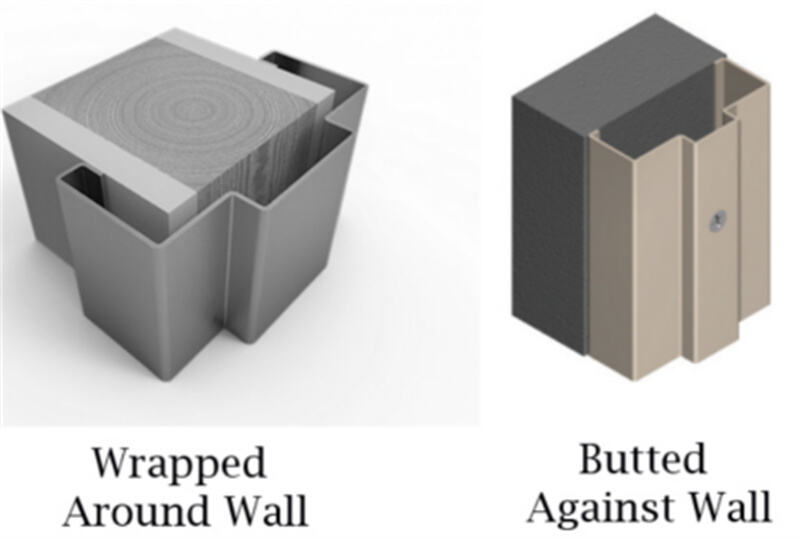

(2) Classified by installation method

Type characteristics Suitable for wall

Anchor Frame - Embedded when concrete is poured

- Optimum stability of concrete walls

Slip-on Frame - fixed by metal fins

- Applicable to steel gypsum wall and light partition wall that has been built

Adjustable Frame - Allows ±1/2" thickness adjustment

- Compatible with irregular walls with different wall tolerances

Key points:

The double-notch door frame must be equipped with a fireproof expansion strip; otherwise, it cannot pass the UL certification.

The anchorage interval of the embedded door frame should be no more than 12" (required by NFPA 80) to ensure that it does not fall off in case of fire.

3. Fire performance and certification

(1) Fire rating matching

The fire rating of the steel door frame must be greater than or equal to the door door (for example, a 1.5 hour fire door needs a 1.5 hour door frame).

Us standard common fire rating:

20 minutes (Level C) : Low risk areas (such as storage rooms)

45 minutes to 1.5 hours (Class B) : Commercial buildings, corridors

3 hours (Level A) : High risk areas (e.g. chemical plants, stairwells)

(2) Key certification standards

UL 10B: Standard for Fire resistance test of fireproof door frames (Open flame + High temperature test)

UL 10C: Dynamic Fire Resistance test for fire door frames (Simulated fire airflow impact)

NFPA 80: Specification for Installation of fire door systems (anchorage, clearance requirements)

Key points:

Steel door frames must be UL 10B/10C tested and permanently marked with UL certification number.

High fire rating (≥90 minutes) The door frame should be filled with fire retardant plaster or mineral wool.

4. Installation and sealing requirements

(1) Installation Specification (NFPA 80)

Anchorage spacing: ≤12 inches (30cm), to ensure that the fire will not fall out of deformation.

Gap between door frame and wall: ≤1/8", sealed with fireproof glue.

Expansion bolt: high temperature resistant (such as stainless steel).

(2) Sealing system

Intumescent Seal: expands in response to heat to fill door cracks (UL 1784 certified).

Smoke Seal: Prevents smoke from penetrating (ASTM E283 airflow test).

Key points:

Door frames without fire seals cannot pass acceptance!

Steel door frames are usually paired with 3/4" thick fire doors to ensure overall system compliance.

5. Market application and selection suggestions

(1) Typical application scenarios

Commercial buildings (office buildings, shopping malls) : 45 minutes to 1.5 hours steel frame + single notch

Industrial facilities (warehouses, factories) : 3 hours steel frame + double notch + expansion seal

Public safety areas (stairwells, machine rooms) : thickened steel frames for 2-3 hours

(2) Suggestions on selection process

Confirm fire rating (according to architectural drawings or NFPA 101 Life Safety Code).

Select door frame construction (single/double notched, embedded/extended wing).

Check wall type (concrete, steel frame, light wall).

Additional requirements (skid resistant, acoustic seal, corrosion resistant coating

Any further information contact me please

E-mail:[email protected]

Website:https://www.ulfiredoormfg.com/Products

Recommended Products

Hot News

-

UL fire door Regulatory and Certification Requirements

2025-08-08

-

What are the types for fire Doors?

2025-07-12

-

Why Hollow Metal Doors Are a Cost-Effective Long-Term Solution for Businesses

2025-07-23

-

What’s the price difference for UL LISTED FIRE DOOR of mahogany/oak/ beech/walnut veneer finish compared with Formica /TAK/ Wilsonart Laminated finish ?

2025-07-31

-

What is MDF (medium-density fiberboard) Door?

2025-06-15

-

Essential Aspects of UL Metal Fire Door Inspection

2024-01-02

-

XZIC Delivers Superior Quality UL Fire Doors to Our Valued Client in Qatar

2024-01-02

-

Can hollow metal doors be insulated?

2024-01-02

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

FA

FA

AF

AF

MS

MS

SW

SW

BE

BE

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

MI

MI

MN

MN

MY

MY

KK

KK

MG

MG

SU

SU

TG

TG

UZ

UZ

KY

KY

XH

XH